HO Keystone Locomotive Works / Northwest Shortline Drive

This locomotive kit, while exquisite, was not designed to be powered. The NWSL kit has four limitations which can easily be overcome, resulting in a smooth-running Shay. Note that some drawings are copyright from NWSL, used for editorial purposes only.

Improved "Cardan Shaft" Driveshaft

The first thing I did was to make new "cardan shafts" for the under chassis drive. I used brass tubing and wire, drilling a hole right near the end of the brass tubing for the wire to slip through. I then bent the wire a bit so it extends just beyond the end of the shaft. Unlike the endpieces in the NWSL kit, this means the shafts won't have a tendancy to pop out on even the tightest corners (see below, NWSL cardan shaft on top).

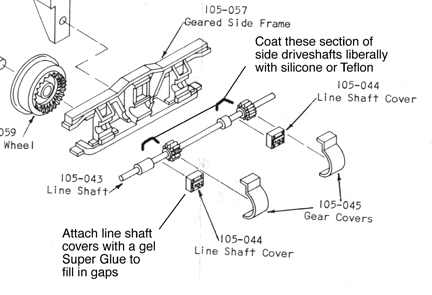

Sideframe and Side Driveshaft

Note that the side driveshafts are for appearance only - power is supplied by a drivetrain under the Shay. The sideframes are soft metal, with a bit of slop to them. You need minimal shifting to get this drivetrain to run smoothly.

What you need to do is to use a gel-type super glue (cyanoacrylate) to fill any gaps. This is especially important with the side driveshaft. However, super glue will stick to metal. You need to coat the side driveshaft with a tiny amount of Teflon or silicone lubricant. When you glue the covers on the sideframes over the side driveshafts, use the gel super glue. Immediately twist the side driveshafts, to be sure the glue doesn't make them seize up.

If done properly, the lubricant keeps the super glue gel from sticking, and when this glue hardens you have the side driveshaft secured in a smooth, tight hole in the sideframe.

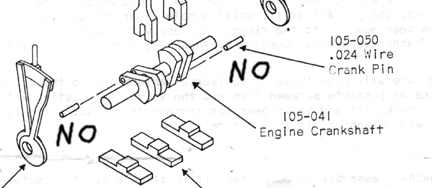

Engine Crankshaft

As mentioned, the side driveshafts are for show. There is nothing better than seeing the cylinders in the Shay's engine going up and down. However, it is literally a nightmare to try and synchronize all of these parts, given the small size and inherent slop in the soft metal castings. The first thing to do is use the straight rod for the crankshaft; don't worry, you won't miss the action of the cranks. Do not install the small crank pins. Better yet - replace the soft metal shaft with brass rod.

Side Driveshaft and Jackshafts

The actual drive system from NWSL is a work of art, and I am not trying to slight them. As I mentioned, the Keystone Shay kit was designed as a static model.

Do not use the smaller square parts of the universal joints that NWSL provides to make the side jackshafts. This should be replaced with brass tubing of a suitable size to fit easily inside the larger square tubing that NWSL provides.

One of the brass rods is left round. This allows the particular truck connected to that end of the side drivetrain to spin freely in response to the real driveshaft under the locomotive.

The other brass rod is slightly flattened with pliers - it should be flat enough to catch inside the square brass tubing, but be narrow enough to slide freely. This allows the particular truck connected to that end of the side drivetrain to transmit power from the real driveshaft under the locomotive to the engine block. If this is set up properly, there is no need to try and synchronize front and rear trucks.